The 8-Second Trick For 24??media

Table of ContentsLittle Known Facts About 24??media.24??media Things To Know Before You Get ThisIndicators on 24??media You Need To KnowAn Unbiased View of 24??media24??media Things To Know Before You Buy

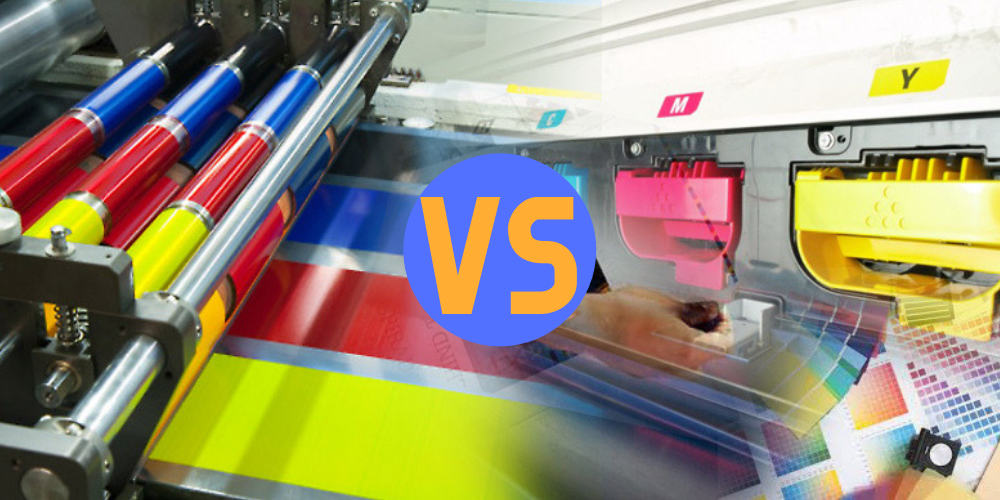

Improvements in print modern technology are changing the communications playing area when it involves quality, cost and cutting-edge abilities. Offset printing and digital printing are the major processes by which print work are undertaken both making use of four-color printing methods. Each option has its advantages, using various techniques to fulfill the demands of diverse manufacturing tasks.

Typically, this has been one of the most consistent technique for specifically keeping color suits, making it perfect for print runs that just call for fixed printing such as pre-printed types, pamphlets, leaflets, calling card, and mass postcard mailings. Nonetheless, as a result of the fixed nature of litho printing, it is not perfect for variable print pieces that will be mailed to private receivers such as statements, letters, and personalized postcards.

What Does 24??media Do?

The most up to date advancements in print innovation are assisting to bring much of countered's benefits into the digital printing world absolutely changing the face of modern-day printing! There are some key distinctions between Offset Printing and Digital Printing (Custom Printed Packaging). This guide shows the benefits and drawbacks of each printing technique. There is an undeniable and growing number of advantages to making use of the electronic print procedure.

Today's digital print equipment is amongst one of the most innovative on the marketplace. Right here are some of the greatest benefits of using electronic printing: dominate the digital print room, with full-color printing finished in one process and perfectly printed directly from a print file. Without a prolonged set-up process, the calibration time of a certain job is reduced, adding to quicker print time and overall delivery.

The inkjet printing procedure has actually helped to transform the market along with the high quality and speed of the outcome. The current inkjet innovation can print on traditional balanced out supplies with plain, silk, and glossy surfaces. Top quality electronic print combined with software-managed shade administration practices adds optimum value to print items and makes production procedures much more dependable than countered.

The Main Principles Of 24??media

(https://go.bubbl.us/e88fc9/fed7?/24??Media)

Green and eco-friendly inks and printer toners are additionally offered for more sustainable printing. Digital print likewise gets rid of the requirement to clean plates or blankets with harmful chemicals at the end of the printing procedure.

Variable information helps companies reach their precise consumers and target market with uniquely-created and personalized material. As modern technology boosts, the high quality of digital printing has actually ended up being second-to-none, with greater detail, shade suit abilities and general precision. Without the need to wash plates or use excess ink, electronic printing is additionally much less inefficient and normally extra eco-friendly.

Standard printing techniques, such as countered lithography ("offset") and flexography ("flexo"), involve several make-ready actions to transfer an initial image to a substratum. These methods require the production of a series of plates placed on a cyndrical tube to move ink that forms the preferred image when incorporated on paperboard and other product packaging products. Large Format Printing.

The smart Trick of 24??media That Nobody is Talking About

Digital printing, with fewer relocating pieces, is more dexterous than offset in this respect.

It's a method to mix your click this site packaging and advertising approaches. Decreased set-up time conserves money on the front end. And considering that these are not large bulk orders, smaller sized businesses can pay for to print without needing to fulfill the higher and much more pricey print thresholds of traditional printing. Digital printing helps shield your brand against counterfeiting by including overt and hidden remedies on your packaging.

Make certain you work together with a printing and product packaging companion that has the right accreditations. While eleventh-hour printing and modification are a significant advantage, electronic might not always be the most effective technique for you. Balance out printing has the advantage of cost-effectiveness with big print runs, especially those with advanced ornamental impacts and specialty finishes.

Getting My 24??media To Work

Lithographic presses use two print platesa positive and a negativeto transfer premium shade graphics onto a suitable substratum. The favorable plate, with its smooth surface area, brings in oil-based inks and wards off water. In comparison, the adverse plate, with its harsh appearance, takes in water and drives away oil. Rubber rollers are after that made use of to move the picture from home plate to the corrugated surface area.

Corrugated paper can occasionally show to be a difficult surface area to print on, but Litho prints to a different surface and is after that laminated to it, making it easy to publish premium images. It can be incredibly regular, also for long terms. The extra you print, the less expensive the costs come to be for Litho.

If you have sufficient time and spending plan, and a big volume of a single layout, after that there should not be a problem. What Litho does not offer you is specifically what Digital does, modification. Extra on that particular later. Expensive established Longer turnaround No Variable Data Printing Smaller sized color range, colors can be much less brilliant Digital printing is the process of printing electronic images straight onto the corrugated substrate using a single-pass, direct-to-corrugate method - Signage.